EpiX - 10X SUPEROXALLOY ABRASIVES

SOLVES “PURSUIT OF EXCELLENCE” CHALLENGES

Choose EpiX superoxalloy abrasives for

demanding manufacturing applications..

- Fabrication, device and

equipment manufacturing - Specialty parts and coatings

When surface quality matters:

- Exacting surface quality, profile, appearance and uniformity

requirements

- Zero tolerance for iron contamination or embedment

- Ultra-low blasting abrasive dust

High-efficiency manufacturing and fabrication processes:

- Speed: reduce time required for surface preparation

- Produce clean, finished surface in one step, with no required

secondary finishing, cleaning or polishing

- Reduce blasting media consumption: contain and reuse abrasives

- Reduce/eliminate throughput disruption caused by rework

Efficient, precision coating removal:

- Remove thick, tough powder coatings, elastomerics, multi-layers, two-part epoxies—with no burn off or scraping

Strict environmental, health and safety blasting requirements:

- Clean blasting abrasives

- Ultra safe

- SSPC-AB 1 Class A (Less than 0.1% Free Silica)

- Extremely low dust

- Sustainable 100% recycled material

- Unparalleled environmental safety: air and water quality - Can be harmlessly left on the ground or in water (TCLP)

EpiX GRADES

Enhanced, uniform profile for extra hard or tough coatings, including mill scale removal.

Uniform, medium profile. Removes extra-hard or tough coating, oil, dirt and grease, leaving an SP 5 finish.

EpiX Packaging Options

• 2,000 LB. Supersacks

• 100 LB. bags

• 50 LB. bags

Superoxalloy vs. powder coat: Removing tough coatings in a matter of seconds

The Challenge:

A painting contractor was hired to clean, repair and recoat specialized hanger hooks coated with a thick and extremely hardened powder coat. They were forced to bake and hand-scrape the hooks to remove the coating because abrasive blasting was not effective. Even silicon carbide could barely dent the coating after minutes of blasting in a small area.

The 10X Breakthrough:

As seen in the photos, 10X superoxalloy abrasive immediately cut through the thick powder coating and left a clean, profiled surface ready for recoating. The entire hook was cleaned and restored in 19 seconds.

EpiX superoxalloy abrasive: Quantum leap in productivity, quality, manufactured part yield and profitability

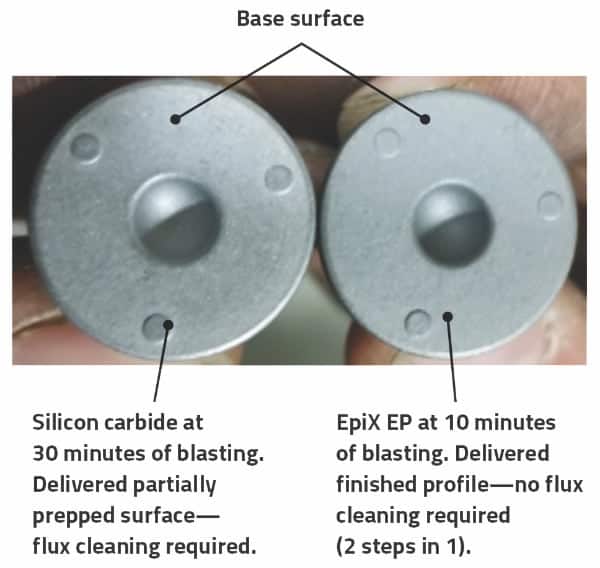

The Challenge:

Asphalt milling and removal bits are submitted to extreme pressure (up to 8,000 PSI). Bits are formed from tungsten carbide and require blasting to remove a carbonized coating left over from the manufacturing process.

Using silicon carbide, blasters would spend 30-60 minutes cleaning the surface before treating the underside of the tips with flux cleaning agent and then brazing the tip to the base of the part. Often the brazed bits would fail in testing and require rework.

The 10X Breakthrough:

With EpiX EP superoxalloy abrasive, 10 minutes of blasting delivered the desired surface profile and eliminated the need for flux cleaning, reducing surface preparation time by 67%. The brazed bond, test without flux, did not fail. At 18,000 PSI, the tungsten carbide tip cracked. EpiX EP delivered a clean bond that exceeded the strength of tungsten carbide.

EpiX superoxalloy abrasive: Quantum leap in productivity, quality, manufactured part yield and profitability

EpiX Ordering Information

| Stock # | Profile | Packaging | Reusability @100PSI | Bulk Density |

|---|---|---|---|---|

| KX1052 | EpiX EP - Enhanced | 2,000 lb SuperSack | 4 - 8 times | 100-110 lb/ft3 |

| KX1054 | EpiX EP - Enhanced | 100 lb Bags | 4 - 8 times | 100-110 lb/ft3 |

| KX1058 | EpiX EP - Enhanced | 50 lb Bags | 4 - 8 times | 100-110 lb/ft3 |

| KX1062 | EpiX MP - Medium | 2,000 lb Bags | 6 - 12 times | 100-110 lb/ft3 |

| KX1064 | EpiX MP - Medium | 100 lb Bags | 6 - 12 times | 100-110 lb/ft3 |

| KX1068 | EpiX MP - Medium | 50 lb Bags | 6 - 12 times | 100-110 lb/ft3 |

NEED MORE INFORMATION?

Please complete the form below. An Allredi technical sales expert is standing by to serve you.

Questions? Need more information? Let's hear 'EM

We will get back to you as soon as possible.

Please try again later.

Ph. 905-527-6000 / 888-794-5665

All Rights Reserved | Allredi Blast and Abrasives Canada Inc.

© 2022 All Rights Reserved |

Allredi Blast and Abrasives Canada Inc.